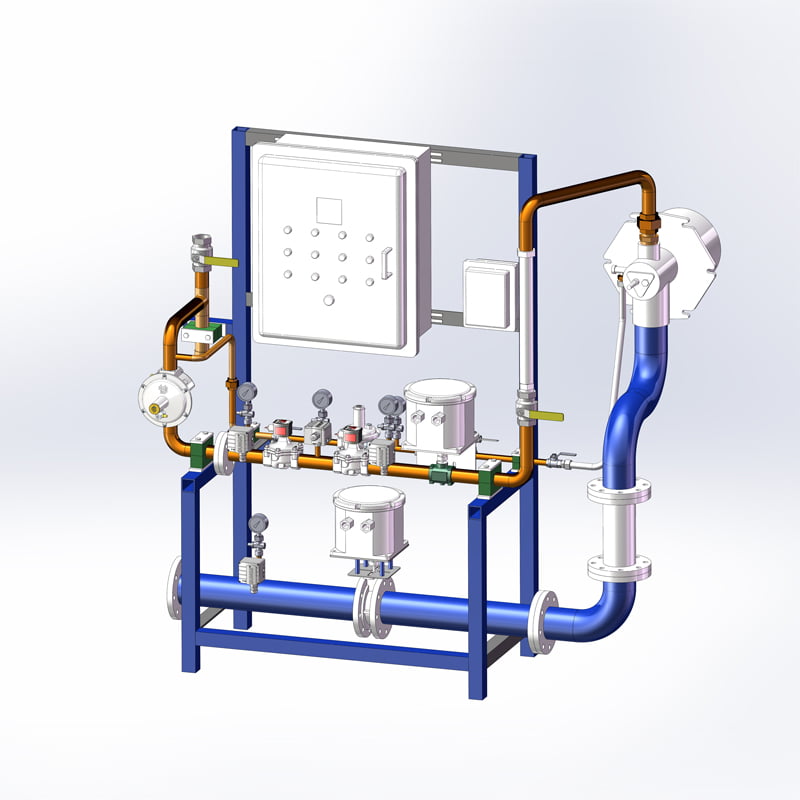

Our industrial combustion system solution for the Chemical Materials and Titanium Dioxide Industry focuses on integrating process-specific thermal precision, multi-fuel adaptability, and real-time intelligent regulation—delivering stable, uniform heat output tailored to calcination, drying, and other core processes in chemical materials and titanium dioxide production, optimizing combustion efficiency to cut energy consumption, reducing harmful emissions (NOx, SOx, etc.) to meet strict environmental standards, and ensuring seamless compatibility with existing production lines while safeguarding material purity, product quality consistency, and long-term operational safety, thereby enhancing overall production efficiency.

-燃烧系统.jpg)