Shanghai Yan Controlled Industrial Technology

PRECISION

COMBUSTION

Reliable, compliant, and cost-effective heating solutions from

30kW to 80MW.

Engineered for global factories, trusted by industry leaders.

ISO 9001:2015

Systematic Quality

Control Management

CE Compliance

European Safety

Machinery Directive

EX / SIL 3

Hazardous Location

Technical Rating

Class A Power

Special Equipment

Certified Manufacture

Skid-Mounted

System Solutions

10+

Year Service Life

Global Compliance Expertise

Strict adherence to ISO 9001 and international norms EU 50mg/m³ NOx, SCAA, and EPAct. Marine systems compliant with IMO standards.

Multi-Fuel Adaptability

Our systems seamlessly handle Natural Gas, LPG, Hydrogen, and future sustainable fuels like LNG/Methanol.

Full-Spectrum Production

Equipped with 4 strategic factories, we integrate R&D and QC using premium components from Honeywell and Emerson.

How We Deliver

Ensuring high-precision execution from discovery to commissioning. We handle technical complexities so you can prioritize performance.

The Foundation

Deep Discovery

& Analysis

We don't guess; we engineer. We start by analyzing your process parameters: fuel availability (Gas, Oil), target NOx emissions, and thermal load (30kW-80MW).

-

Site Requirement Audit

-

Global Regulation Check (EU/EPA/IMO)

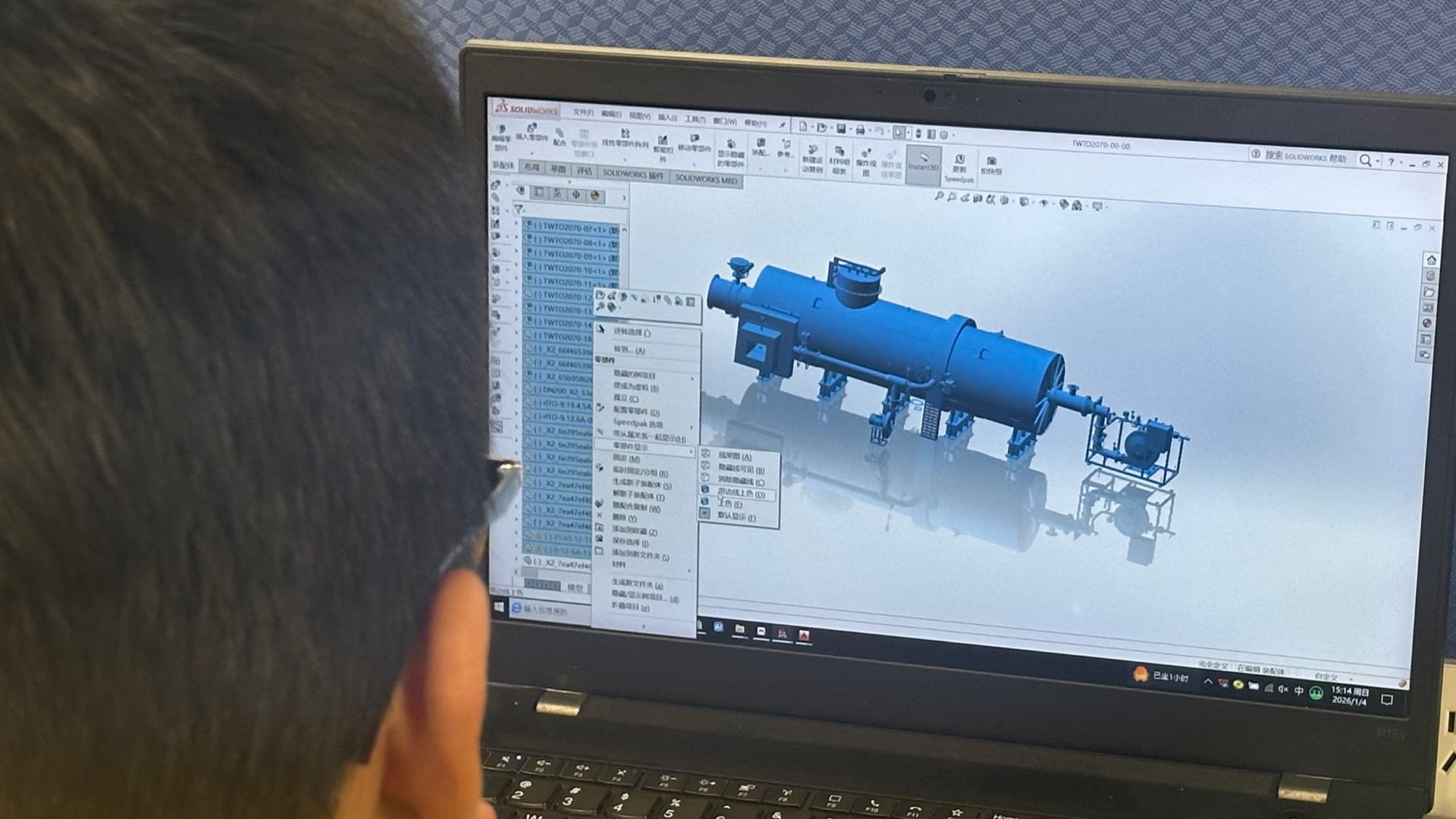

Precision Design

Skid & System

Engineering

Our team creates full 3D models of your combustion skid. We optimize piping layout to minimize footprint and simulate flow dynamics to ensure safety.

-

3D Visualization & P&ID

-

BMS Integration Logic

Quality Control

Fabrication

& Testing

Manufactured in our ISO 9001 certified facilities. Every valve train and burner undergoes strict cold-testing and leakage checks before crating.

Mission Accomplished

Delivery & Tuning

We don't just ship; we ensure performance. Our engineers travel globally to supervise installation, perform fine-tuning, and train your staff.

Start Your ProjectProduction Strength

World-Class

Manufacturing Base

Precision

CNC