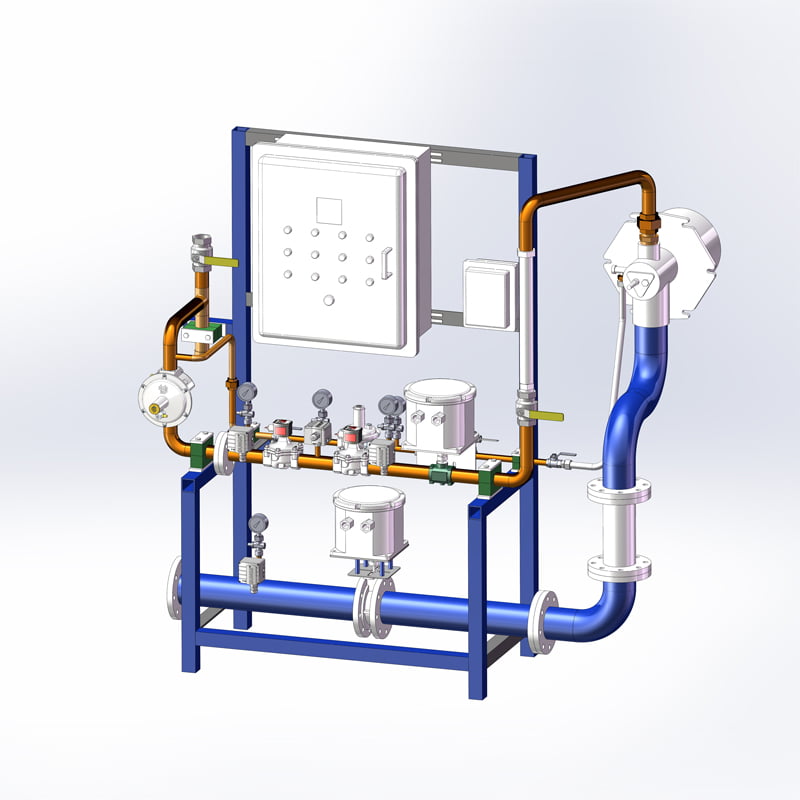

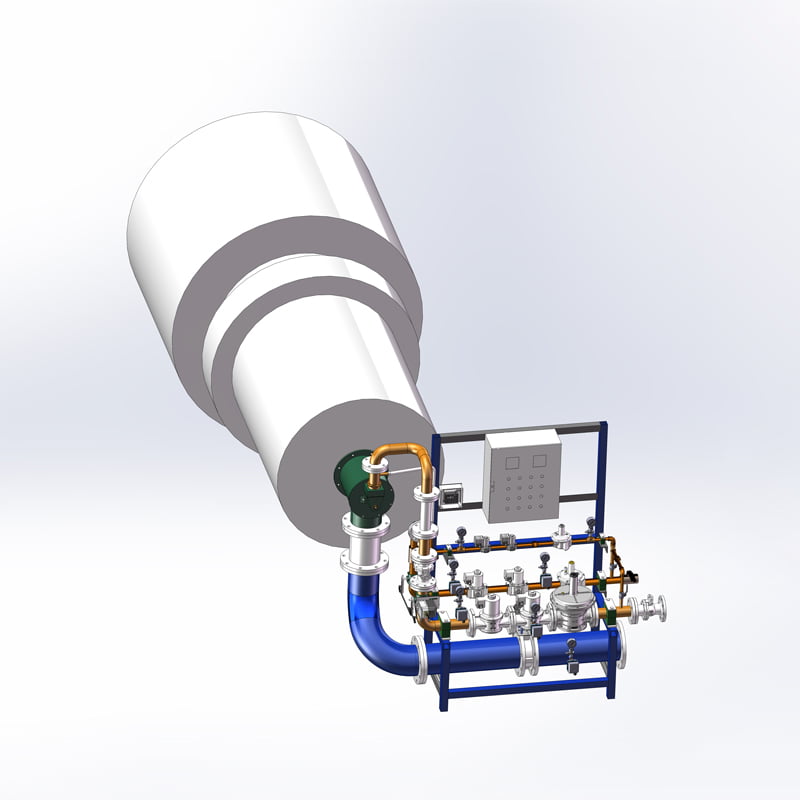

Our industrial combustion system solution for Calcination Kiln is core to aligning precise, material-specific thermal profiling with energy efficiency, environmental compliance, and operational reliability—integrating flexible fuel adaptability (gaseous, liquid, or solid fuels based on on-site availability), real-time monitoring of key parameters (temperature, oxygen, pressure), and closed-loop intelligent control to optimize combustion efficiency, minimize energy waste, reduce emissions (NOx, SOx, etc.) to meet global standards, while featuring robust, harsh-environment-resistant design for long-term stable operation and seamless integration with existing workflows, enabling scalable adjustments to adapt to varying production loads and calcination process requirements.