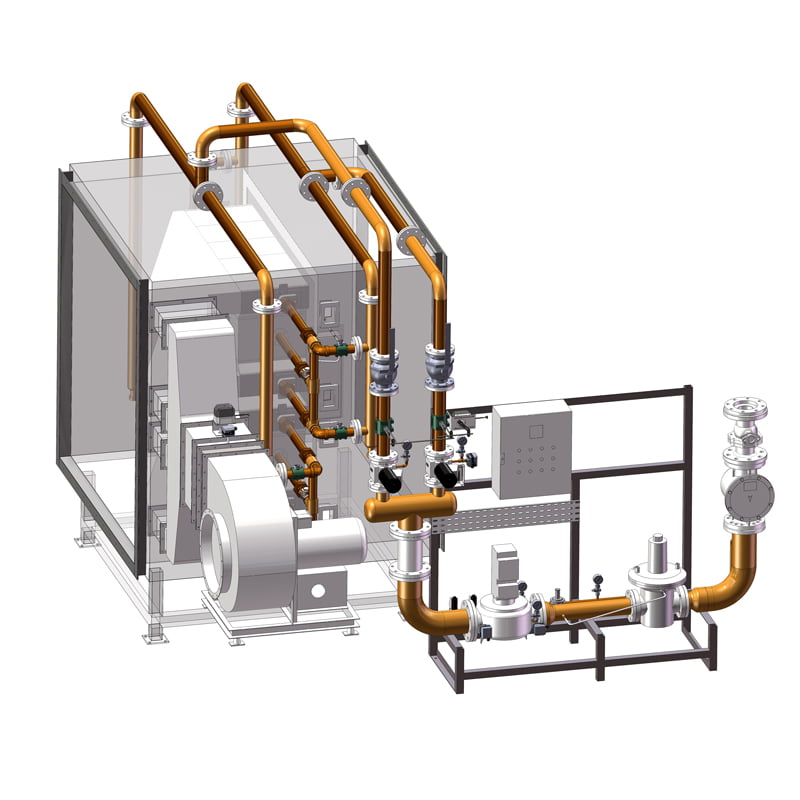

For the building materials processing industry’s drying sector, our industrial combustion system solution revolves around delivering stable, high-efficiency heat sources tailored to the drying requirements of materials such as gypsum boards, gypsum powder, and mineral wool boards, achieving precise temperature control to meet process-specific heat treatment demands and ensure consistent product quality, optimizing combustion to enhance thermal efficiency and reduce energy consumption and operational costs, guaranteeing uninterrupted production through reliable system performance, and providing flexible controllability to adapt to diverse building material drying needs—comprehensively balancing quality, efficiency, and sustainability.

Nozzle-mixing