-

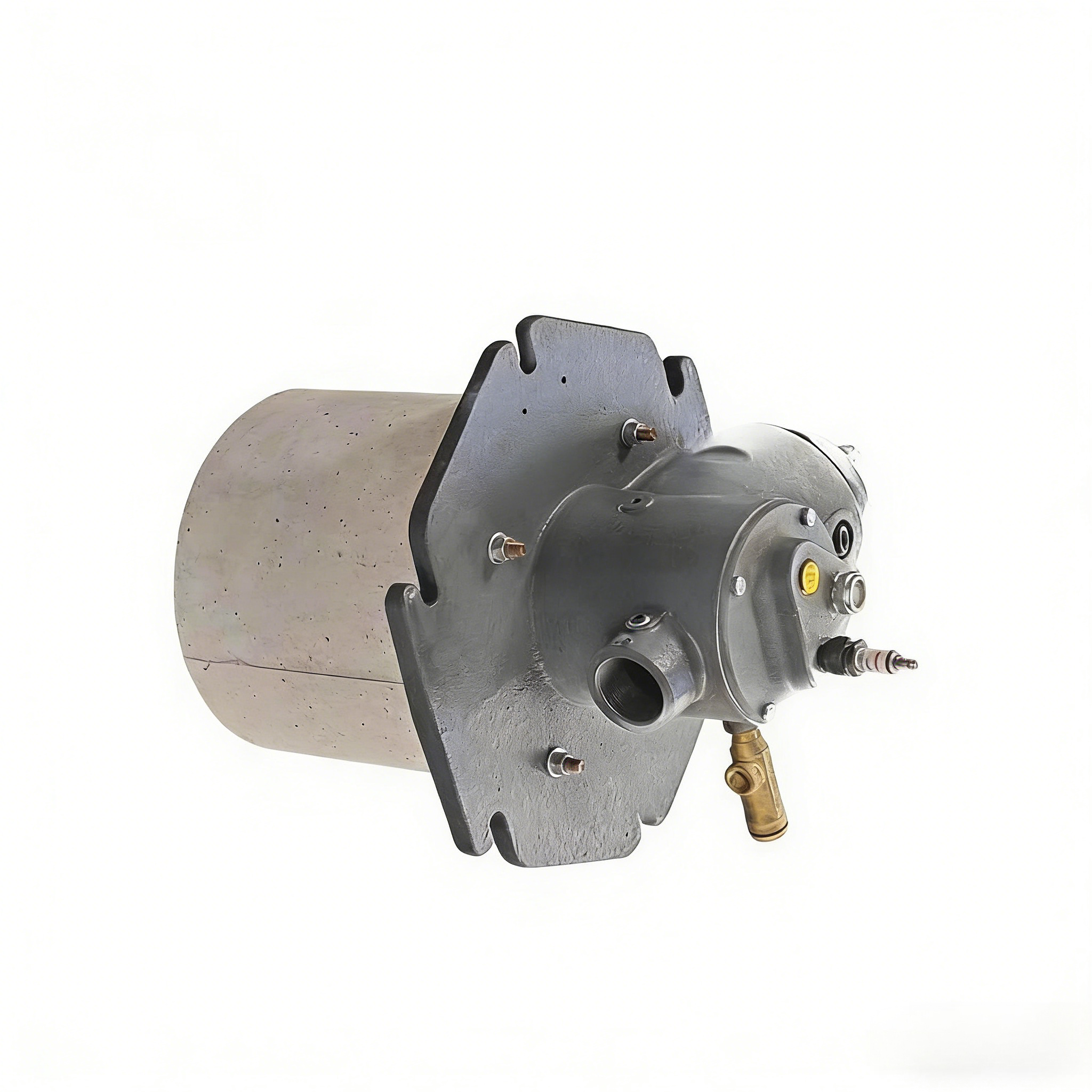

Heatflam KM Series Gas Burners

Nozzle-mixing, medium velocity gas burners for high-temperature furnaces, delivering superior temperature uniformity and workload heat penetration. Versatile operation, fuel efficiency, and durable design for industrial heating needs.

Core Highlights:

- Nozzle-mixing technology: Enhances combustion gas circulation for uniform heating

- High exit velocity: Up to 300 km/h (85 m/s) for optimal heat penetration

- Excellent turndown ratio: Up to 48:1 for flexible load adaptation

- Fuel compatibility: Burns clean low-pressure gases (natural gas, propane, hydrogen blend, etc.)

- Fuel-efficient: Works with preheated air (up to 425°C/800°F) to reduce consumption

- Oxygen-enriched air compatible: Adaptable to specific combustion demands

- High temp tolerance: Refractory blocks support max 1650°C (3000°F) chamber temp

- 5 size options: 110–2348 kW (0.38–8.0 MBtu/h) to fit diverse applications

- Compliance: ANSI/ISO standards; Eurasian Customs Union certified

- Easy maintenance: Removable backplate for inspection & upkeep

- Durable construction: Gray iron housing, castable refractory blocks, carbon/stainless steel components

- Application focus: High-temperature furnaces (heat treatment, melting, ceramic, oxidizers, kilns)

- Flame supervision: UV-scanner or flame rod for reliable safety

- Configurable: Air/gas connections, block materials, mounting flanges & test kits

- Inquire for quote & full specs!

KM

Product Information

Product Description

Downloads

Need Customization?

Our engineering team can customize this system to your exact process requirements.

Chat on WhatsAppRelated Products

HBG

Heatflam HBG Series Industrial Burners High-performance industrial burners for diverse heating scenarios, covering multiple sub-series for small-to-large scale demands. HBG specializes in gaseous fuels; HBC supports multi-fuel use. Both offer ambient/preheated (up to 900°F/482°C) air, reliable ignition and strict safety monitoring for efficient, stable operation. HBG Series (Gaseous Fuel-Specific) Gas-optimized combustion systems with sub-series 1004/2004/3004 […]

View Details

Ovenpak 400

Model 415 OVENPAK® Burner with connecting base and linkage assembly to adapt customer’s automatic electric control motor Burns any clean fuel gas Fires into passing air streams Requires only low pressure gas Provides clean combustion with low NOx levels Compact burner design provides quick and easy installation Simple field adjustment and maintenance

View Details

HBC

Heatflam HBC Series Burners Versatile industrial combustion systems for diverse heating applications, with multiple sub-series (1104/2104/3104 to 1124/2124/3124) for broad capacity needs. Multi-fuel (NG, LPG, No.2/No.6 fuel oil) compatible, supporting ambient or preheated (up to 900°F/482°C) secondary air. Low/high-pressure atomization (gaseous/No.2 fuel oil; No.6 fuel oil) for stable combustion. Capacity: 310,000–124.55M BTU/hr (80–32,940 kW), flexible […]

View Details